We do careful Inspection

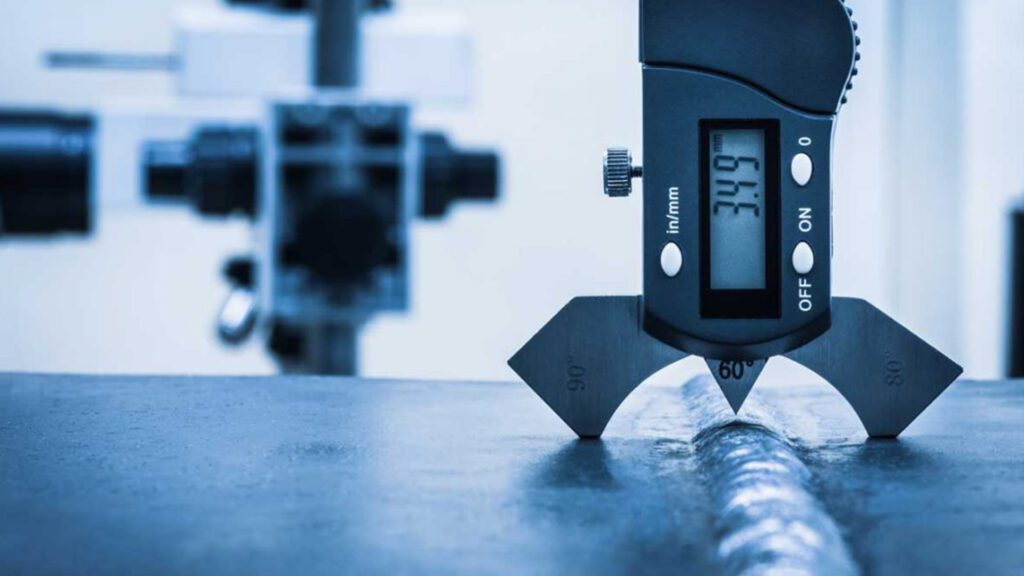

we are expert in delivering reliable and accurate inspection services to a diverse range of industries. Our highly skilled inspectors utilize advanced techniques and state-of-the-art equipment to thoroughly assess the condition, safety, and compliance of your assets and equipment.

We offer a wide range of inspection services, including visual inspections, non-destructive testing (NDT), structural integrity assessments, and more. Our team has expertise in various inspection methods such as ultrasonic testing, magnetic particle testing, liquid penetrant testing, and radiographic testing. With our meticulous approach, we identify defects, vulnerabilities, and potential risks, enabling you to make informed decisions for maintenance, repairs, and asset management.

We provide following Industrial Inspection and Integrity Assessment Services.

Plant turnarounds, also known as shutdowns, due to maintenance, fault and inspection of the equipment and are one of the most crucial events in the routine operation of plants. we offer a wide array of inspection and manpower supply services during annual turnarounds for industries like chemicals/petrochemicals, process, oil & gas, sugar, steel, oil and power generation.

We provide in-service and risk based inspection of storage tanks, pressure vessels, Pressure safety valve testing, fire tube boilers, Heat Recovery Steam Generators and pipelines as per specified API codes and standards.

we offer comprehensive upstream tubular inspection services to ensure the integrity and reliability of your oil and gas tubular assets. Our expertise in non-destructive testing and advanced inspection techniques allows us to deliver accurate and timely assessments, helping you make informed decisions regarding your tubular assets.

Inspection Capabilities: Our skilled inspectors are trained to perform a wide range of inspections on various types of tubular assets, including drill pipes, casing, tubing, and downhole tools. We utilize advanced non-destructive testing methods such as electromagnetic inspection, ultrasonic testing, visual inspection, and magnetic particle inspection. These techniques allow us to detect defects, corrosion, cracks, and other abnormalities that may compromise the performance and safety of your tubular assets.

Indegrity supports upstream exploration and production (E&P) activities in the oil & gas industry with specialized inspection, maintenance, monitoring, data management, and access solutions in following sections.

Indegrity welding inspection services ensure your welds meet required quality standards, leading to reduced failure rates and extending the potential operating life of components. Our welding specialists hold internationally recognized qualifications, including the Certification Scheme for Welding Inspection (CSWIP), Personnel Certification in Non-Destructive Testing (PCN), and Certified Welding Inspection (CWI).

We combine a global team of trained and certified inspectors to provide a complete range of third-party, independent weld procedure and weld engineering services for energy, aerospace & defense, transportation, and construction sectors.

Feel free to contact us or just drop a line. Our support staff will get back to you soon.

+92-335-4675668,

+92-333-8406330

042-32357093

customercare@indegrity.com

6-A, HBFC Faisal Town, Lahore, Pakistan, 54000

Address:

6-A, HBFC Faisal Town, Lahore, Pakistan, 54000

Mobile: +92-335-4675668,

+92-333-8406330

Landline:042-32357093

Contact:+92-321-8476720

Email: customercare@indegrity.com